Technological advancements have led the way from manual labor to automated machines finishing up difficult tasks. Manufacturing is one of the important sectors where machines took human’s place and made jobs easier. One such machine that made life easier was the CNC(Computer Numerical Control) machine. These machines have changed how you think about manufacturing tasks; these machines provide accurate parts and a safe and flexible work environment that reduces the workload in your workshops.

CNC machinery has become an essential component in any workshop dealing with production and manufacturing. Different types of CNC machines are available in a CNC machine shop. These machines vary in price, size, load-carrying capacity, and production speed. Finding the right machine that matches your needs and budget is critical to avoid investing more and avoid production delays.

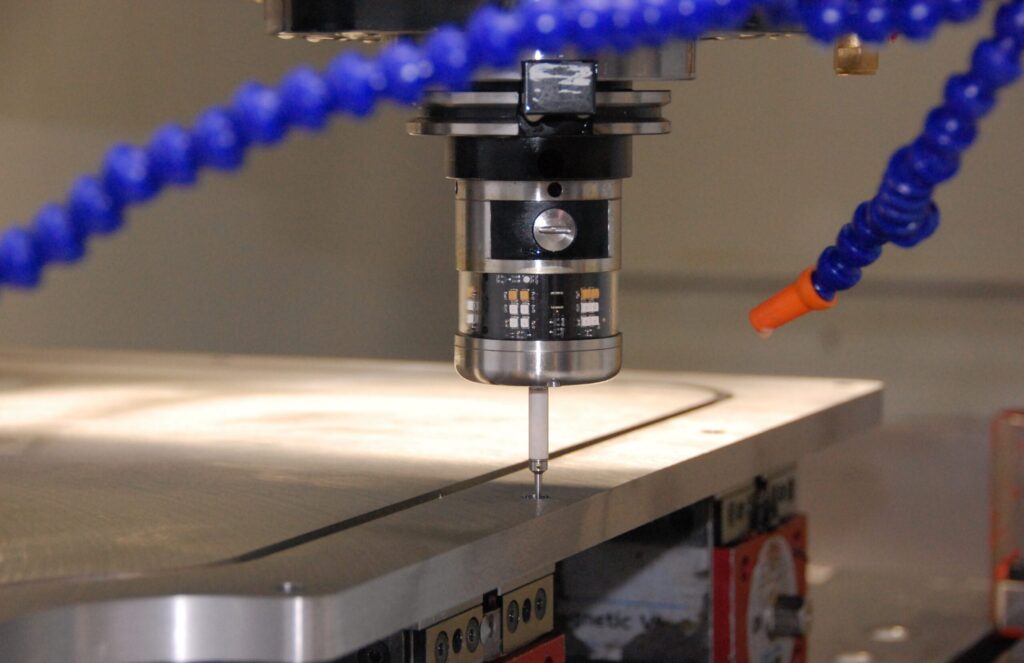

What Is A CNC Machine?

Source: pinterest.com

A Computer Numerical Control machine involves a computer that is connected to the machinery. The computer controls the machinery by processing the instructions it receives and directs the machinery to carry out different operations. CNC programming is done on the computer to perform different machining operations. The computer then illustrates what is to be done on the screen, and modifications to the program can be made easier depending on your requirements.

This helps in the following:

- Preventing Wastage.

- Achieving Consistent Results.

- Avoiding Failure.

- Achieving Automation And Mass Production.

Some Of The Commonly Used CNC Machinery

Some of the commonly used CNC equipment that are integral in the production and manufacturing of different components are :

- Computer Numerical Control Router

- Computer Numerical Control Milling

- Computer Numerical Control Lathe

- Computer Numerical Control Plasma Cutter

- Computer Numerical Control Waterjet

- Computer Numerical Control Laser

- Computer Numerical Control Driven Electrical Discharge

- Computer Numerical Control Grinding

- 3D-Printer

These are the most commonly used CNC machinery, but a CNC machine shop also requires other components and equipment, like a Drill Press, Coordinate Measuring Machine(CMM), Metal Bending Machine, Welding Machine, and so on. These types of equipment help in the smooth functioning of a workshop as many unprecedented activities might need to be carried out in the course of work.

Factors To Be Considered While Selecting A CNC Machine

Source: facebook.com

Assess The Existing Setup: Before jumping in and transforming your workplace, it is important to analyze your existing setup to see if upgrading to a CNC shop is necessary. Since this can be a huge investment, future perspectives and order predictions can also be worked out to see if the machine will help you attain a profit and help you get back the investment.

Part Design And Complexity: Analyzing your workshop’s commonly manufactured parts is critical. This will help set the highest standard you need while purchasing the machine. Analyzing the parts and the accuracy needed will help you choose the type of machine to help you deal with the most common large-quantity orders.

Raw Material: The nature and type of the raw material used determines the highest RPM, torque and horsepower you will ever need. Understanding the raw material helps to purchase equipment that can complement the rigidity of the material used and helps maintain the machine’s performance, durability and precision.

CNC Control System: CNC control system acts as the center for all the machining operations. All the controls and instructions are often given out using this system. It is important to realize that the CNC control system does not need to be fancy, but it should fulfill all your basic requirements and is reliable, user-friendly, and effective in acting as the control center.

Average Cost Per Unit And Budget: Investing in these machines does not guarantee you any profits. It is important to analyze and understand your order quantity and determine how much the new machines will cost you per unit of sale made. It will also be worth discovering how long it might take to recover the investment and achieve a break-even point.

Manual Vs. Automated Machines: Which One Do You Need?

Source: youtube.com

Manual labor has been used by humanity since the days of industrialization; it was only in the late 2000s that these equipment were appreciated, and since then, it has outgrown popularity. Some of the key improvements that can be achieved by using Automated CNC machines are :

- Higher Accuracy And Precision: Manual labor fails to produce consistent results; accuracy and precision vary from unit to unit. In the case of CNC machines, once the program is finalized, it is easy to produce uniform units without much difficulty.

- Less Production Time: Manual labor is often time-consuming; depending upon the nature of materials, it can take up many labor hours, while automated machines can reduce this to mere minutes.

- Increased Productivity And Wastage Reduction: Due to the possibility of continuous operation, automation can boost productivity and reduce fatigue in human beings. These equipment are only affected during maintenance, while manual labor is affected by holidays, sick leaves and other issues. Due to the accuracy of parts, wastage of units can be kept to a minimal level.

- Safer Work Environment: As manual labor involves many dangerous operations to be done directly by human beings, it poses a workplace risk. Automated machines have eliminated this, and there is minimal risk to human beings.

Tips To Keep In Mind During Your CNC Machine Purchase

Source: youtube.com

It is important to remember the minute details regarding CNC machines while purchasing, as these details can greatly impact performance. Some of these include:

- Availability Of Spare Parts: Like any other machinery, these machines can also need occasional repair and maintenance, so it is important to pick machines that have spare parts readily available in the market. Delay in maintenance and repair can affect the business badly; thus, getting them up and running as soon as possible is important.

- Power Consumption: The power supply available in the workshop might be unable to power up huge CNC machinery. Thus it is important to consider the power consumption of the machines before finalizing the purchase. This can help in planning any upgrades needed at the workshop to accommodate the powerful machinery

- Weight Of The CNC Machine: Most common materials used for the construction of these CNC machines include aluminum, polymer composite and Iron Cast. The iron cast built machines are the heaviest and work best for heavy metal applications, while others are more suitable for light operations.

Conclusion

CNC machines have changed how humankind manufactures different machinery and appliances. These machines have revolutionized the manufacturing industry and reduced workplace accidents that might have occurred due to manual labor. They have become a mandatory piece of equipment in any workshop. Thus it is important to keep updated with the techniques and applications of these machines to stay competitive with your production workshop.