Lathe has existed in the manufacturing industries for years and is known for its efficiency. Its combination with the sophisticated CNC technology takes the precision and accuracy of its cutting, milling, and rotating process to new heights.

Today, medical industries quest to produce medical devices and instruments with high accuracy and precision to meet stringent medical requirements. This made them turn to advanced manufacturing techniques that produce accurate machining services.

The CNC lathe cutting-edge technology is a game-changer in achieving the critical production factors – precision, accuracy, and reliability – of medical needs. Its ability to produce materials with tight tolerance and high precision machining services makes it indisposable for medical applications.

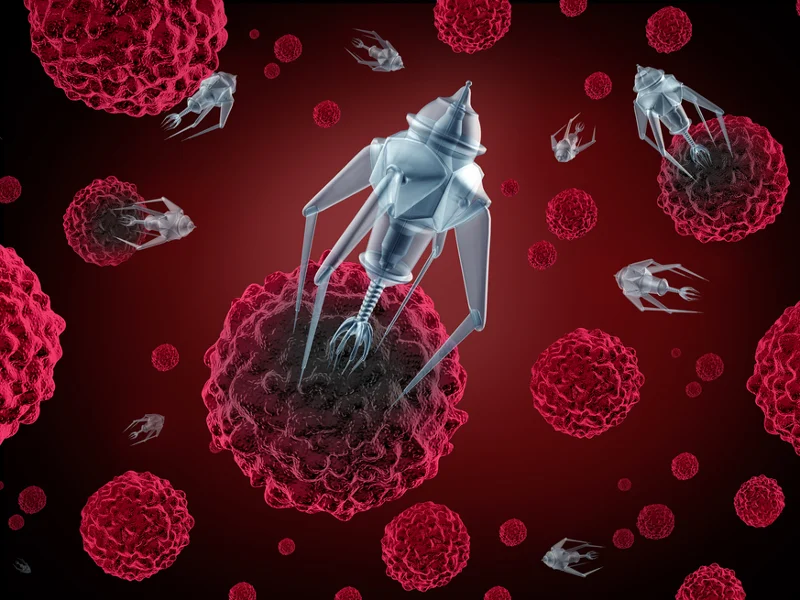

Nanotechnology and Micromachining

Source: medicaldevice-network.com

To patient care, the precision machining services of the Lathe coupled with the accuracy employed during the machining process is significant in producing medical devices of nano- and micro-sizes. The nano-sized particles and material machined in the Lathe found extensive application in nanomedicine. They are used as novel diagnostic, imagery and methodologies, biomedical implants, and tissue engineering.

Conversely, the micromachining-enabled process of CNC lathe made it possible to machine implants, instruments, and medical components that are ever too small to produce and require a high level of accuracy. For example, the nanotechnology and micromachining system provides a safer and more consistent delivery of medication internally, such as insulin pumps, and cisplatin (cancer drug) delivery more effectively and safely as encapsulated nanoparticles.

Also, the lathe machining technology’s precision machining services have produced parts small enough to fit into the eye to restore vision as intraocular implants. Precision machined parts help cardiologists save lives through the aid of stents, microscopic screws, and pacemaker parts used to repair anatomic damaged parts of the heart.

CNC lathes’ nanotechnology and micromachining ability aren’t just for material, tools, and equipment that have contact with the body. It can be used to manufacture electronic medical devices such as heart rate monitors, MRI scanners, and radiography machines.

These devices require many complex parts, and the CNC lathe can fabricate these complex shapes and bring life out of the devices. Because these devices require a high level of standards to prevent failure, therefore, you cannot underestimate the role of a CNC lathe in machining its parts.

Implants and Bodily Replacements

As a versatile and advanced machining tool, the CNC lathe excels in the field of completely milling materials such as titanium known for its exceptional strength and resistance to corrosion to produce innovative designs as implants and body replacements with its 6-sided shaft.

With its six-sided shaft, the CNC lathe rotates, mill, and cut feed material with high precision machining services to produce the innovative design of the medical components.

Generally, the lathe shaft works closely like the spindle which with its high speed of rotation machines the material to produce products with stringent dimensional requirements. These products are then used as implants and body replacement.

Conversely, the combination of Computer Numerical Control (CNC) with lathe further enhances its accuracy for machining body replacement with tight tolerance. This is because the numerical input processes the lathe mill or cuts the exact dimension giving the tolerance rate.

Repetitive Accuracy for Mass Production

Source: mindflowdesign.com

Medical shops often need to produce large quantities of identical components of medical devices and equipment, such as bolts, screws, nuts, and complex parts. And manual machining of these components may lead to variations in the final products due to human error.

The manual machining process relies heavily on the expertise and precision of the operator. Despite the best effort, it’s almost impossible to be consistent in dimensions with a large number of production, leading to inaccuracies.

Employing the CNC lathe minimizes the need to rely on human accuracy, making repetitive and consistent accuracy of identical components possible. This phenomenon is vital for the manufacturing process in medical industries.

In addition, less reliance on manual skill in machining parts with stringent dimensional requirements significantly results in accurate machining services.

Intricate Designs of Surgical Instruments

The CNC lathe can operate as a turn and mill machine to produce intricate designs of surgical instruments such as surgical hammer and other intricate designs of medical device components.

This process of machining is achieved by feeding the machine with the material and it begins to rotate the blank while cutting, CNC, and removing materials to produce the basic skeleton of the instrument. The six-sided shaft then aids rotation and continuous milling of delicate parts to achieve the exact dimension and shape of the surgical instrument.

Furthermore, the CNC lathe machine also uses a variety of other cutting tools like end mill and drills to perform several operations like hole drilling on the surgical instruments, grooves creation, and slots for functional and aesthetic purposes. All of these and use of other tools contributes to surgical instrument design and achievement of the final surface finish.

With this technology, surgeons can now make speculation of the type and design of surgical instruments for complex procedures and the Lathe brings it to life. These innovations to medical shops improve patient care.

Rapid Prototyping and Iterative Designs

Source: nuvation.com

Fabrication of physical parts and organs design from 3D computer aided design (CAD) of prosthetic parts such as leg and shoulder is possible with CNC lathe.

The high precision machining service of CNC lathe is employed in this field. The design for each patient’s need is done on CAD and inputted to the lathe. The Milling and cutting process of lathe at high revolution per minutes enhances the prototyping process while ensuring accuracy.

With this, medical professional can now evaluate and test the component as soon as possible before mass production. In addition, the rapid prototyping process give medical shop edge to meet market demand

Conclusion

The impact of the CNC lathe technology in medicine, surgery, and biotechnology is unparalleled. Its advent has brought a significant revolution to the medical industry in terms of the accuracy and precision of medical device manufacturing. From intricate designs of surgical instruments and implants to nanotechnology and micromachining, lathes have transformed the medical industry and improved the ability to deliver safe and effective products for patient care. The lathe precision machined parts’ reliability reduces error risk, leads to safer medical procedures, and improves patient care.